Protecting Your Boat From Galvanic Corrosion

Protecting your boat from various external elements is crucial in the long run. Our boats are made of many processed materials that want to return to their normal state by undergoing electrochemical processes - in other words, these materials want to corrode. Corrosion-resistant metals rely on an oxide film for protection. So for example, stainless steel has a tightly adherent, stable, and self-healing film, while steel has a loose, powdery, and easily damageable film.

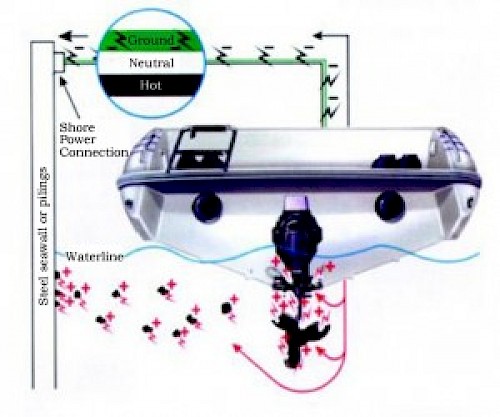

Galvanic corrosion occurs when two dissimilar metals, for example copper and steel, are connected and submersed in an electrolyte (water) - this creates an electric charge. Negative electrons from the negatively charged metal (anode) will flow to the more positively charged metal (cathode). Left alone, the charged metal will corrode away to nothing. Now let's say you dock at a pier with steel pilings or a steel seawall, and then plug into shore power. The ground wire, which is grounded, connects your underwater components with the submerged steel because the steel is also grounded. Considering the mass of a seawall or even a single piling, your drive and propeller can sustain serious damage. This damage could be prevented with a galvanic isolator.

What are some common signs of galvanic corrosion that you can look for? Well firstly, you will notice paint blistering, especially at sharp edges. Also, you will notice a white powdery substance and the metal becoming pitted. This is because metal is actually being eaten away! Now let's look at stray current corrosion. This is when electricity from an outside source flows into your boat's metal components and out through the water for a ground. The current direction flow determines which metal will corrode, and when there are high currents, corrosion occurs quickly. To prevent or reduce stray current corrosion, here are some pointers to keep in mind:

- Use marine-rated electrical equipment only

- Use quality multi-stranded, tinned wire with quality terminals

- Keep electrical wiring out of damp areas

- Eliminate fuses and switches on the grounded negative side

- Return wiring should be at least as large as positive cable

- Check your vessel for reversed polarity

- Use high quality bottom paint

- Ensure you have a galvanic isolator

By ensuring you follow these pointers, you can save yourself money and time, and also maintain your boat so that it runs efficiently for as long as possible. If you have any other areas in boat maintenance that you think we should talk about, please let us know and we would be glad to write about it.

Related Content

$379.00

$379.00 $263.21

$263.21